Chlorine is a powerful disinfectant that kills most microorganisms, including bacteria, viruses and protozoa.

Pure chlorine is a gas and is extremely hazardous, however, stabilised chlorine products (liquids and solids) are safer, affordable and widely available. These products are commonly used for disinfecting drinking water in various humanitarian situations:

- In a piped water distribution system.

- Into water trucks.

- Added to buckets / jerrycans of water collected from handpumps either manually by attendants or automatically by dispensers.

- Continuous chlorination of dug wells.

- As part of household water treatment products.

A key advantage of chlorination over other disinfection methods is that a residual may remain in the water, preventing recontamination. It is also relatively affordable, widely available, can be dosed without specialist equipment, and is easy to measure. However, it does need to be handled carefully, and the monitoring and dosing need to be carefully managed to ensure proper disinfection of the water.

The aim here is to make easily accessible, technically sound, practical guidelines for humanitarian programmes. Authoritative sources have been used and referenced where possible, and additional advice is given based on experience.

Technical Efficacy

Factors Affecting Efficacy

Chlorine’s efficacy depends on:

- The concentration of chlorine dosed into the water

- The pH of the Water. Chlorination is most effective at a pH < 8.0. Where the pH is greater than 8.0, higher free residual chlorine concentrations and/or more contact time will be required.

- The contact time. This is the length of time that the chlorine is in the water. The minimum contact time is 30 minutes. 11

- Temperature. The standard contact time of 30 minutes applies at 25°C, but this must be doubled with each 10°C temperature drop.

- The chlorine demand of the water. Chlorine reacts with organic and inorganic material in the water, and this chlorine is not available for disinfection. This includes iron and manganese, which are often found in groundwater.

- The types of pathogens in the water. Chlorine is very effective against bacteria, and slightly less effective against viruses, then protozoa. Some pathogens are chlorine resistant.

Turbid Water

Turbid water is typically caused by suspended organic and inorganic particles in the water. This will reduce the effectiveness of chlorination because:

- It indicates the presence of substances which will react with chlorine, and increase the chlorine demand.

- It may ‘shield’ microorganisms from the effect of the chlorine.

Where source water is turbid (greater than around 10 NTU2) either:

- Find an alternative source

- Pre-treat the water before chlorination, using either a filtration or sedimentation process to reduce turbidity. This should preferably be through the use of coagulation/flocculation with Alum, then sedimentation.

- Double the chlorine dose. While this is not recommended in the long term, this can maintain adequate free residual chlorine and effectively reduce microbiological contamination at turbidities up to 100 NTU.2 At higher turbidities than this chlorination is not recommended.

Disinfection by-products

Disinfection by-products are a perception, rather than a real risk in emergencies.2

Chlorine can react with organic material and bromine in the water to form disinfection by-products (DBPs), including trihalomethanes (THMs). Some of these are possible human carcinogens, and the World Health Organisation (WHO) has established guideline values for these. These guidelines values are based on the ‘acceptable risk’ of one extra cancer case per 100,000 people who drink two litres of chlorinated water per day for 70 years. Research has found that even with turbid water the presence of THMs can be below WHO guideline values.2

The risk is therefore very low, especially in comparison to the significant health benefits from disinfection of water. According to the WHO Drinking Water Quality Guidelines:1

“In all circumstances, disinfection efficiency should not be compromised in trying to meet guidelines for disinfection by-products, or in trying to reduce concentrations of these substances.”

Chlorine Resistant Pathogens

Some pathogens have resistance to chlorination, and cannot be deactivated by chlorine at normal doses.

Cryptosporidium and Ascaris are two of these pathogens.

If chlorine resistant pathogens are thought to be a risk, then they can normally be removed by additional treatment steps before chlorination including sedimentation, filtration, or coagulation/flocculation.

Break-point Chlorination

Chlorine undergoes three types of reaction when added to water: 3

- Firstly, substances such as manganese, iron and hydrogen sulphide dissolved in the water will react irreversibly with chlorine. This reaction removes these substances, thereby improving water quality and taste. The chlorine which reacts this way is, however, lost and does not contribute to disinfection.

- Secondly chlorine may react reversibly with organic matter and ammonia in water. The compounds formed are weak disinfectants. The products are referred to as combined chlorine.

- The remaining chlorine will react with the water, forming efficient disinfectants. This is free residual chlorine (FRC).

Chlorination for water supply normally uses ‘break-point chlorination’, whereby enough chlorine is added to satisfy the first two reactions, and then more chlorine is added beyond this ‘break-point’ to create free residual chlorine for the purposes of disinfection. There is another type of chlorination – chloramination – which uses a lower but carefully controlled quantity of chlorine and ammonia. This is not normally used and is not recommended in humanitarian settings.

The “chlorine demand” of the water is defined differently in different publications, and is either the chlorine required for the first irreversible reaction, or for the first irreversible reaction and also the second, reversible, reaction.

Free Residual Chlorine

What is FRC?

Free Residual Chlorine (FRC, sometimes termed the free chlorine residual – FCR, or Free Available Chlorine – FAC) is the portion of the chlorine dose which forms a powerful disinfectant, after the chlorine demand of the water has been used up. FRC remains in the water after the initial disinfection has occurred, but will decay with time.

FRC is easy to test for, and the presence of FRC indicates that enough chlorine has been added to inactivate most pathogens, and also that there is still some protection from subsequent contamination. For these reasons FRC is a key parameter to monitor in chlorinated water supplies.

What are appropriate FRC levels?

Chlorine dosage and FRC are usually measured in milligrams per litre of water (mg/l), or parts per million (ppm); both mean roughly the same thing.

The chlorine dosage should be set to achieve a target FRC. In a water distribution system FRC will vary depending at which point in the water delivery process it is measured, and not all recommendations make clear where in the water supply chain this should be measured.

Advice on levels of FRC is extremely inconsistent.2 The Sphere Standard is that there should be “≥0.2–0.5mg/l FRC at point of delivery”.5 This is based on the WHO Drinking Water Quality Guidelines, 6 which state: “for effective disinfection, there should be a residual concentration of free chlorine of ≥ 0.5 mg/l after at least 30 min contact time at pH <8.0. A chlorine residual should be maintained throughout the distribution system. At the point of delivery, the minimum residual concentration of free chlorine should be 0.2 mg/l.” 1

The WHO standards are appropriate when the user is expected to drink the water immediately after it flows from the tap.4 In humanitarian settings water is often collected far from the household and stored for a significant period of time. Therefore it has been proposed that 0.2 mg/l should be the minimum FRC at household level, at the time of consumption. 6 2 If the receiving water has a pH >8.0, the FRC will need to be higher to give the same level of disinfection, so in these situations so at the point of consumption the FRC should be a minimum of 0.4 mg/l. 7

In practice, large variations will be found when measuring the FRC at point of consumption, even for the same system. This is because water will have been stored for different lengths of time, and in different conditions. Therefore, for day-to-day operation of a system more consistent and easier to control FRC targets will be needed. Typically this would be at water distribution points, or upon leaving a water treatment plant.

Based on data from Ali et al6, reasonable target values for FRC at water distribution points would be:

- Good WASH Conditions, cool temperatures: 0.5 mg/l

- Poor WASH Conditions, high temperatures: 1.2 mg/l

The FRC level as water is leaving a treatment plant or water trucks would need to be higher than these figures. This is because the FRC will decay before reaching the water distribution point.

Some publications recommend increasing the dosage during disease outbreaks, or in an emergency with a high risk of disease outbreaks.2

Once the system is running it is possible to conduct research comparing FRC at the water distribution point with FRC at point of consumption, and to use this to optimise the FRC target for water distribution points. To do this effectively a proper research method and analysis needs to be established. Attempting to do this without a proper method and close supervision could be counterproductive – readings of FRC at household level are likely to be variable, making analysis complicated, and care needs to be taken over how the FRC is measured: some common ways of testing for FRC would be unable to distinguish between water with an FRC of 0.2 mg/l and water with no FRC at all.

The FRC should never exceed 4.0 – 5.0 mg/l 2, although many individuals would find the taste and smell of the water unpalatable at levels much below this. Taste thresholds, and the point at which the water becomes unpalatable, are extremely variable but it is likely that chlorine levels above 1.0 – 2.0 mg/l will become unacceptable. Some people may even find chlorine levels as low as 0.2 mg/litre disagreeable. It is possible to conduct taste testing with the water consumers to find what is acceptable for the local context.

If users find the taste unpalatable, they may prefer to use alternative, less safe, water sources.

How to measure FRC

There are several different ways to measure FRC. The selection of the method used will depend on the local availability, skill of the operators, budget, and accuracy required (which is likely to be related to the accuracy of the dosing method). Below are the methods likely to be used in a humanitarian WASH programme.

DPD 1

The measurement of chlorine levels in drinking water with DPD (N,N diethyl-p-phenylene diamine) was pioneered by Dr A T Palin in the 1960s. It is now an international standard method (ISO 7393).

When DPD 1 tablets are added to water it will turn pink in proportion to the level of FRC in the water. DPD 1 tablets are very commonly used in humanitarian settings.

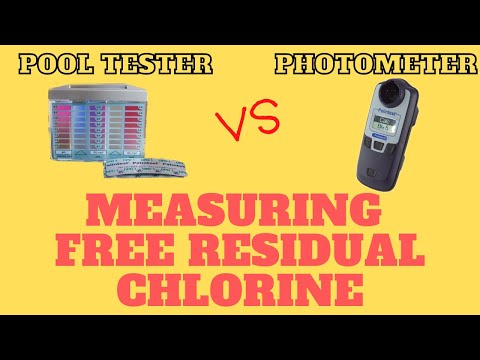

There are two tools commonly used to measure the shade of pink:

- Pool Testers. Compare the colour of the water containing DPD 1 with patches of colour printed next to the water on the pool tester. Each colour corresponds to a particular level of FRC. Often pool testers can also be used to test pH using phenol red tablets. Pool testers are very cheap and it is easy to understand how to use them. However, they are not precise and their accuracy is limited by having to make judgements about which colours match; different people can read different values from the same test.

- Photometers. More expensive, photometers provide a much more precise and accurate reading. They determine the FRC level by shining a light through the water containing DPD 1 and reading the colour.

The following video includes a demonstration of how to use both tools:

Note that there are two types of DPD 1 tablet:

- DPD 1 Rapid tablets. (“Effervescent” tablets) this is for use in pool testers for reading by eye only. It has an additive which means that it will dissolve quickly without needing to be crushed. However, this additive increases the turbidity of the water and will result in erroneous readings from a photometer. For DPD 1 tablets provided by Palintest, ‘DPD’ on these types of tablet is written in green (Palintest code AT010).

- DPD 1 standard/normal tablets. These are for use with a photometer, but can also be used in a pool tester. These tablets will need to be crushed in the water to make them dissolve – they will not dissolve by shaking. For DPD 1 tablets provided by Palintest, ‘DPD’ on these types of tablet is written in black (Palintest code AP011).

DPD 1 tablets will measure FRC in a range between approximately 0.2 – 5 mg/l.

If the FRC concentration is above around 10 mg/l it can cause bleaching of the colour, and it may falsely appear as though there is no FRC in the water.

Both pool testers and photometers can be used to measure total residual chlorine as well, through the addition of DPD 3. The process is not the same as when using DPD 1. Follow the manufacturer’s instructions to do this.

In rare situations, it is possible that when testing water with low levels of chlorine (the dosage has not reached the break-point) the solution can gradually turn more pink over the course of a few minutes, giving a false reading. The correct chlorine reading is obtained by measuring the colour of the water immediately after the DPD 1 has dissolved. 8

Test Strips

Chlorine test strips are easier to use but less accurate than using DPD 1.

They also come in a wider range than DPD 1, making it possible to test stronger solutions without dilution. The appropriate type of test strip should be selected based on the expected strength of FRC in the water:

- Low (0 – 5 mg/l): testing for FRC in treated water

- High (0 – 2000 mg/l = 0 – 0.2%): for use in some disinfecting hand wash solutions

- Very High (0-10,000 mg/l = 0 – 1%): for testing disinfecting solution. Note that this would not be suitable for testing FRC levels in a chlorine solution prepared for dosing, as it would not be accurate enough.

The full specification, pictures and price of testing strips are available from the Oxfam Supply Centre.

Automatic FRC Loggers

There are tools available which can be used to automatically detect and log levels of FRC in a pipeline. They can also be used for remote monitoring.

These systems are expensive and complex to use. They have not so far been widely used in humanitarian situations, but their use is being explored and they may become more common in future.

Monitoring FRC

Monitoring FRC will be a routine activity in running any chlorinated water supply system.

It is important when setting up a monitoring system to remember that the primary purpose should be so that the dosing levels can be corrected. There is no point in collecting many FRC readings only for them to be filed away unused.

As discussed regarding the appropriate FRC levels, there can be two types of monitoring:

- Operational monitoring at water distribution points. This should be compared against the target value and used to set the dosing level in the system. It is possible that this might be measured at the outlet of a water treatment plant instead. This should take place daily, and can reviewed weekly to ensure that the dosing levels are correct and to make adjustments if necessary.

- Household level monitoring. This can be undertaken to check that there is still FRC at point of consumption. This is more complicated than operational monitoring, so careful consideration should be given in to how or whether to do this.

The Safe Water Optimization Tool is a free and open-source, web-based water quality assurance tool designed to help ensure adequate FRC is maintained over the last mile of distribution – from the tapstand to the point-of-consumption. The tool uses FRC monitoring data collected from tapstands and households to model the site-specific chlorine decay, considering factors such as ambient temperature, raw water quality, and water handling practices, that can impact how quickly FRC decays.

Forms of Chlorine

Chlorine can be found as a solid, a liquid, or a gas; and is often combined with other substances. The strength of chlorine within a substance is referred to as the concentration of active chlorine, and is typically expressed as a percentage. It may also be expressed in degrees chlorometrique, a unit often used by former French colonies, where 1% active chlorine = 3.16 degrees chlorometrique. 2

Pure chlorine is a gas (or liquid if pressurised) and is often used in conventional water treatment. However, it is very hazardous and difficult to handle and is generally not suitable for use in humanitarian emergencies.

In humanitarian situations chlorine normally either comes in liquid or solid form.

Sodium hypochlorite (NaOCl, bleach, Javel water) is a liquid, and typically contains from 1 – 5% available chlorine, although concentrated solutions can contain up to 18%. Typically a sodium hypochlorite product will also contain 0.01-0.05% sodium hydroxide, which is used to slow down the decomposition of sodium hypochlorite. In some places it is produced and sold specifically for household water treatment. Additionally, regular domestic bleach can be used for household water treatment, provided that it is not scented, colour safe, or contains any added cleaners (it should be indicated on the label that it is safe to do so).9 There can be significant differences between advertised and measured strength of commercially available bleach.10 It is also available in larger quantities for water treatment, but as most of the product is water it is not normally economical to transport.11

Sodium Hypochlorite solution can also be made on-site from a salt water solution using electrolysis. This could be an attractive solution where it is logistically difficult or costly to use another form of chlorine. Chlorine generators are available from the Oxfam Supply Centre.

Calcium hypochlorite (Ca (OCl)2) is available in solid form as:

- Bleaching powder (chlorinated lime). A white powder which is a mixture of calcium hydroxide, calcium chloride and calcium hypochlorite. It typically contains 20% to 35% active chlorine12.

- High Test Hypochlorite (HTH). Normally found as granules, but also available as a powder or as tablets. It is stronger than bleaching powder, containing 65% to 70% active chlorine. It is also easier to use as it comes in granular form, and is also more stable and is therefore preferred over bleaching powder where it is available.

- Tablet form, with added materials to prevent powdering, stop moisture being absorbed too readily, and in some cases assist desolving.

Calcium hypochlorite will form an inert precipitate when mixed with water which will block pipes or dosing equipment. This means the preparation of solutions using calcium hypochlorite is a more involved process, as the solution needs to be left to settle and then decanted before using.

NaDCC (sodium dichloroisocyanurate or troclosene sodium) also comes in solid form. It is normally available as granules or tablets, but can also be found as a powder. In granular form it is typically used for large scale bulk water treatment, whilst tablets are used for smaller quantities (from 1 to 2000 litres) and can be packaged for household water treatment (for example Aquatabs). It typically contains around 60% active chlorine in tablet form, or 55% as granules. It does not contain any inert material. It is also less corrosive than calcium hypochlorite and sodium hypochlorite. In comparison to calcium hypochlorite it is less stable when in solution. NaDCC is available from the Oxfam Supply Centre in 5 kg tubs for bulk water treatment, and strips of 67mg tablets for household use.

Different types of chlorine should not be mixed, as doing so can cause explosions.2

Chlorine is also available in slow-dissolving tablets. These are used in floating-pot chlorinators in water tanks, or in some inline chlorinators. These tablets are commonly sold by swimming pool suppliers. They are available in a variety of sizes and compositions. Trichloroisocyanuric acid tablets are used in the Aquatab Flo, and HTH based slow dissolving tablets are available.

Small sachets containing a mix of chlorine and a flocculant are available for treating turbid water at household level. The chlorine in these products can be either calcium hypochlorite (e.g. P&G Purifier of Water/PuR) or NaDCC (e.g. Watermaker).

Safety and Storage

Chlorine is a hazardous material. All manufacturer’s instructions and applicable safety regulations should be followed. The following advice is from the WHO fact sheets:12

"When handling concentrated chlorine solutions, appropriate precautions should be taken. Ideally, gloves and protective eye glasses should be worn. In the event of splashes and especially splashes to the eyes, it is important immediately to rinse thoroughly with water.

"When a disinfecting agent has to be transported under difficult conditions (for instance on foot), then solid forms (rather than hypochlorite solutions or pure chlorine in cylinders) are advantageous because they are less hazardous to handle. Although solid forms are generally less hazardous to handle, it is good practice to wash hands after handling.

"All containers in which chlorine is stored should be labelled, identifying the contents, and with a hazard warning in a form which is readily understood locally.

"Storage sites for chlorine in any form should be secure against unauthorised access and especially against children."

In addition:

- Chlorine products can be combustible, and should be stored away from organic material.

- Chlorine gas can be formed, which is extremely hazardous and heavier than air. The storage location should be well-ventilated, and chlorine should never be stored in a cellar/basement. 7

- Chlorine should never be stored in the same room as the night watchman is sleeping in.

- Chlorine should also never be stored in any room that people are using (such as an office, living area or dining area).

- Never spray humans with chlorine spray, even as an infection control measure. This has serious detrimental health effects. 13

The strength of stored chlorine will degrade with time. To minimise the degradation, chlorine should be stored in dark, cool, dry places. The containers it should be stored in should be air-tight, of chlorine resistant material.

Disposal of expired chlorine

Unopened containers of HTH and NaDCC have a shelf life of 3 – 5 years. Bleaching powder has a shorter shelf life. Stock should be managed so that the oldest chlorine stocks are used first.

When chlorine passes its expiry date it does not automatically become hazardous, rather its efficacy reduces. This creates a risk that the chlorine will be dosed at the wrong strength and therefore using expired chlorine for drinking water treatment should be avoided. Exceptions can be made as an emergency measure where no other chlorine is immediately available, so long as the strength of the chlorine is tested and the dosing adjusted appropriately.

The preferred solution for chlorine which has passed its expiry date is not to dispose of it, but to store it and use it over time. It can be used for general disinfection purposes where accurate dosing is not required, for example for the cleaning of toilets.

Where this is not possible, small quantities of chlorine can be disposed of by making up a solution of low concentration (e.g. 1000ppm / 0.1%), and then disposing of in a sanitary sewer, flushing with plenty of water.

Large quantities of chlorine must not be flushed into the sewer, as they may kill the bacteria in a sewage works and so stop the biological treatment of the sewage. Similarly, large quantities should not be put into watercourses since it will damage aquatic life.

Larger volumes of chlorine can be disposed of in a chemical waste disposal facility. Many countries do not have such facilities. Burying the chlorine in a hospital hazardous waste pit, double wrapping in thick plastic and without opening the containers, could be an option of last resort.

For more information refer to the interagency Guidelines for Safe Disposal of Unwanted Pharmaceuticals in and after Emergencies.14

Preparation of Solution

Manufacture’s instructions should always be followed.

When using chlorine powder or granules, it should not be directly added to the water being treated. Instead, it should be prepared in a high strength solution and then dosed into the water to be treated.

Strengths of chlorine solution are often measured as a percentage. A 1% solution is equivalent to 10,000 mg/l, or 10 grams of chlorine per litre. The strength always refers to the amount of active chlorine, and not to the quantity of chlorine product added.

Chlorine solution should be prepared at a strength between 1% and 5%. Often 1% solution is made, as the maths is easier and the solution is safer at lower concentrations. However, for larger systems, this can result in large volumes of solution being required, and a stronger solution is preferable. Stronger solution can also be preferable to allow a smaller dosing pump to be used (as smaller quantities of liquid need to be pumped). When using dosing pumps it is often desirable to adjust the strength of the solution to correct for the desired FRC, rather than adjusting dosing rates.

For example, if a system operates at 100 m³/day, and is to be dosed at 2 mg/l. This will require 200 grams of active chlorine per day. If NaDCC with a strength of 50% is being used, this will require 400 grams of NaDCC. If a 2% solution is used, then the 200 grams of active chlorine will be mixed with 10 litres of water.

The steps to prepare a chlorine solution for dosing are as follows:

- Add the required amount of water to the mixing container, which should not be metallic.

- Measure out the required quantity of chlorine. This can be done using accurate scales, but it may be easier in the long run if it is measured in tablespoons (1 tablespoon ≈ 14 grams), or using a marked translucent container and measuring by volume (chlorine in HTH powder form has a density of about 800g/litre).

- Add the chlorine to the container.

- Mix well using a mixing rod, which should not be metallic.

Always put the water into the container first, then add the chlorine. Doing the opposite (water on chlorine) risks a violent exothermic reaction (explosion).

Where using a calcium hypochlorite product (bleaching powder or HTH), it is necessary to take more steps to remove the precipitate:

- Leave to stand for at least an hour so that the inert material can settle to the bottom. Preferably, the solution should be mixed in the evening and left to settle overnight.15

- Decant the solution into the container that it will be dosed from.

- Dispose of the ‘sludge’ of inert material at the bottom of the mixing container.

Chlorine solution should be stored in a closed container, away from light and heat. Calcium hypochlorite solutions can be stable for several weeks but may deteriorate rapidly 16 12, typically 2-4 days of solution can be mixed at one time.15 NaDCC is less stable in solution than calcium hypochlorite, so the solution should be prepared daily. 16 2

It is very common to see chlorine being dosed directly from the container it is mixed in. Calcium Hypochlorite products (bleaching powder and HTH) contain insoluble, inert, material and this often causes problems with pumps and dosing equipment. To avoid these problems is essential to allow the mixed solution to settle and then decant into a second container for dosing.

Determining Dosing Strength

The quantity / rate of chlorine to be dosed needs to be set to achieve the target FRC. Initially, this can be set from typical values, or a bucket test can be carried out. Once the system is running, it is important to verify the real FRC achieved and adjust the dosing accordingly.

Typically, the dosage will be: 2

- 2.0 mg/l in less turbid waters (<10 NTU) and;

- 4.0 – 5.0 mg/l in more turbid waters (10-100 NTU).

It is possible to start a programme using these typical figures. These dosages are also typical of household water treatment products.

The most appropriate dosage will vary from place to place and will vary with time. Therefore, where feasible, the dose should be determined using an experimental procedure before starting the chlorination.

- Prepare a chlorine solution at the same strength as it is expected to be used in the system. Only a small amount (<1 litre) is necessary initially for this experiment.

- Then, prepare several plastic buckets each with 10 litres of the water to be treated. Using a syringe to dose each bucket with a different amount of chlorine solution, so that the active chlorine concentrations in each bucket are, for example, 1 mg/l, 2 mg/l, 3 mg/l, 4 mg/l and 5 mg/l.

- After allowing the appropriate contact time, measure the FRC in each bucket. Determine which dose is closest to the required FRC.

- Repeat the test. This time use chlorination concentrations close to the dose which was most effective in the first round. For example, if in the first round 2.0mg/litre was the most effective, try this time with 1.5, 1.75, 2.0, 2.25, 2.5mg/l.

- The required dosing concentration has now been determined.

Although the maths involved in this is very simple, the mix of units can cause confusion, so the overall supervision of this process will need to be undertaken by somebody with a good understanding of the calculations.

After starting the system, it is extremely important to continue to monitor the FRC, and adjust the dose based on these results.

Ensure the person(s) who undertake the chlorination know how to adjust the dose.

What method should be used to change the dose? Adding more powder to the same volume of water when making the solution? Adjusting the dial on the e-doser? Pouring a greater volume of solution into the chlorination tank?

How much adjustment should be made according to the FRC measured? For example, if the measured FRC is 0.2mg/l below the target, how much extra chlorine powder should they add to the solution?

Methods of Dosing into Water Systems

A variety of dosing solutions are presented below. In Summary:

- For water trucking or batch water treatment, pour the fixed volume of chlorine solution directly into the tank.

- For continuous flow situations without power, either dose into a tank using a constant rate system from a container, or use a Dosatron for higher accuracy.

- Next to boreholes (i.e. where there is power), use an electronic dosing pump. If the system is solar powered ensure that the dosing pump is variable flow.

Other dosing solutions may be used in some situations. This includes suction side dosing, which is often used for alum dosing but is normally less appropriate for chlorine dosing; and the use of inline slow dissolving chlorine tablets, which are often not available locally.

The best place to dose into a water system will be specific to each system. As the dosing should take place in a secure area, it is often best to locate it next to pumps or other infrastructure which will be secure and may already have an operator or guard.

Batch dosing into water tanks

Pouring the appropriate quantity of chlorine solution directly into a water storage tank is a very simple and effective method of disinfecting large quantities of water.

It is particularly effective as part of a batch water treatment plant. It is also the recommended way to treat water in a water trucking operation, with chlorine solution dosed straight into the water tank at the filling point.

The chlorine should still be prepared into a solution beforehand (i.e. the chlorine granules / powder should not be added to the tank directly). It will be necessary to allow the appropriate contact time before opening the outlet of the tank.

The chlorine demand of the water is likely to fluctuate in surface water treatment plants, particularly during the rainy season. An advantage of chlorinating directly into the tank in this situation is that the FRC can be checked after the contact time has elapsed, and if the FRC is inadequate more chlorine solution can be added.

The disadvantage of this is that it is a batch process: the water cannot enter and exit the tank at the same time. It also requires a lot of manual intervention. This means that it is not usually appropriate other than in batch water treatment plants, or in exceptional emergency cases.

Continuous dosing into water tanks

Where water is flowing into and out of a tank at the same time, batch dosing is no longer possible.

In this situation, it is possible to create a constant-flow dosing system, which will dose a very low flow of chlorine solution into the tank continuously.

This is a simple as placing a container of chlorine solution above the tank and letting is flow out from the container very slowly. The challenge however is to keep the flow rate the same no matter the level of chlorine solution in the container. Designs for this can be found in WHO fact sheet 2.2215.

The advantage of this type of dosing is that it is very simple and does not require any specialist equipment to implement. This could be a very good solution in continuous flow water treatment plants, or in gravity systems where the water flows continuously from a spring.

It would be less appropriate in systems which are not running on a continuous basis, as it will need to be turned on and off at the same time as the rest of the system. This would include most pumped systems, where the tank the water is entering would be far from the pump.

Dosing into pipes without external power

It is possible to dose chlorine directly into a pipe under pressure using a water powered, flow activated, proportional dosing pump. One example of this type of pump is the Dosatron.

The advantages of using a Dosatron or similar are that it requires no external power source, is flow activated and doses proportionally to the flow. The latest model of the Dosatron will work on systems with flow rates up to 30m3/hr and pressures from 0.5 to 8 bar (the previous Dosatron kit supplied by the Oxfam Supply Centre worked up to 3 bar).

The disadvantage of the Dosatron kit is that it causes head loss in the system (details are in the user manual). This needs to be accounted for in the design. There have also been reports of the Dosatron blocking – this is likely caused when using calcium hypochlorite based products and not allowing the inert material to settle out.

Find out more about the Dosatron kit from the Oxfam Supply Centre.

Dosing into pipes with electric dosers

Where power is readily available, for example where the main pumps have electric motors, then it will be easy to use electrically powered dosing pumps. These pumps use an external power source to accurately dose fixed quantities of chlorine solution into a pipeline under pressure. In cases where the flow rate is variable, for example because the systems is powered by solar power, it is possible to use variable rate pumps which can adjust their dosing rate automatically as the flow rate in the pipe changes.

All dosing pumps are available in a range of discharges, which can also vary with the pipeline pressure, and it is necessary to calculate the flow requirements for your purpose before ordering the pump.

Although all of the above solutions will have adjustable dosing rates, it is normally simpler after initial setup to make adjustments to the strength of the chlorine solution being dosed, rather than changing settings on the pumps.

The Oxfam Supply Centre supplies fixed rate dosers and variable rate dosers.

The electric doser available from the Oxfam Supply Centre.

Chlorination at handpumps

During a water borne disease outbreak it is necessary to ensure that all water consumed is chlorinated.

For a limited time period, where water is not from a centralised pipe system, it may be easiest to achieve this by dosing chlorine directly into peoples buckets or jerrycans at the point where water is collected – typically from a handpump or well.

This can be achieved by training attendants to use syringes to dose from a chlorine solution into peoples buckets. This is known as ‘bucket chlorination’. Alternatively, the attendant can add household water treatment tablets directly into user’s buckets.

An alternative to this is to install chlorine dispensers at water points, or to install devices onto handpumps which chlorinate the water automatically using slow dissolving tablets. One example of this type of device is the PurAll 50H.

Bucket chlorination in Cox’s Bazar, Bangladesh, and an automatic chlorine dispenser.

Continuous chlorination of wells

Hand dug wells can be susceptible to contamination, particularly if not properly protected or if in a crowded area.

Continuous chlorination of hand dug wells can be undertaken by repeated (e.g. daily) additions of chlorine solution, or by diffusing chlorine into the water continuously (pot chlorination).

Examples of how to do this are shown on WHO Fact Sheet 2.21. 17

This is only likely to be appropriate in very high risk situations as a short to medium term solution whilst a longer term solution is implemented. It has been shown that it can be successful, but is also susceptible to 1) pot chlorinators releasing chlorine too quickly; 2) not maintaining a FRC for long, and 3) giving a false sense of security. 2

Household Water Treatment Products

Broadly, there are three different types of household water treatment products using chlorine.

- Liquid chlorine. Bleach / sodium hypochorite solution which is normally dosed by a household using a bottle cap.

- Chlorine tablets. Chlorine tablets supplied to various amounts of water, typically from 1 litre to 20 litres. Aquatabs, which are NaDCC, are a very common brand of chlorine tablet, but others are available.

- Coagulant and chlorine combination sachets These are suitable for treating turbid water, but are somewhat more complicated to use. Examples of this type of product are PuR and WaterMaker Plus.

Typical doses are 2 mg/l for turbidities < 10 NTU and double that for turbidities >10 NTU. 1

The benefits of using tablets compared with liquids include lower transport cost, longer shelf-life, and ease-of-use. Drawbacks are that tablets are relatively higher cost; need to be imported; and there can be confusion when multiple sizes of tablet are available.2

Recommendations from Branz et al. for household water treatment programmes are as follows: 2

- Provide products with standardized dosage and instructions and accurate concentrations

- Deliver products with a safe storage container

- Direct programmes at households previously familiar with the household water treatment method

- Select implementing organisations with prior experience with the product and programme

- Aim for high access to, demand for, and compliance with products

- Provide the necessary supplies and training

- Utilize community-based mobilisation, education, and marketing techniques

- Consider prioritizing distribution in households that cannot be reached by centralized treatment

All household water treatment interventions require significant promotion work to be effective.

Distribution of sodium hypochlorite solution for househlod use in Mozambique; and NaDCC tablets for household use from the Oxfam Supply Centre.

Chlorine for other Purposes

Handwashing Solutions

Chlorine solutions for handwashing were widely used at medical facilities during the West Africa Ebola outbreak.

Washing hands with 0.05% chlorine solution is similarly effective to soap and water or an alcohol-based hand sanitiser, although it does have the benefit of reducing pathogen load in the rinse water.18

Oxfam do not recommend the use of chlorine-based handwashing solutions, and promote the use of handwashing with soap instead.

Disinfection of Water Supply Infrastructure

Chlorine can be used for the disinfection of water storage tanks, pipelines, hand dug wells, boreholes and water trucks. This is sometimes called ‘shock chlorination’.

For these purposes a chlorine solution of 0.2% (2,000 mg/l) can be used 19 20 21 22. This should be left overnight, and must be removed before the infrastructure is used for water distribution again.

Other sources may recommend slightly different chlorine strengths. 7

When wells are shock chlorinated there is not a long-lasting improvement in water quality.

Disinfection in health facilities

Research has shown that exposure to a 0.5% strength chlorine solution for 15 minutes is an effective way to interrupt disease transmission from spills in Ebola outbreaks. 23

Different chlorine solution strengths are recommended depending on what is being cleaned. The following recommended solution strengths are summarised from MSF’s Public Health Engineering in Precarious Situations, which it is recommended to consult if working in medical facilities.7 WHO’s Health laboratory facilities in emergency and disaster situations is also recommended24

| Strength | Purpose |

|---|---|

| 2.0 % | Corpses, stool or vomit from a cholera outbreak. |

| 0.5 % | Corpses or body fluids from Ebola, or other viral hemorrhagic fevers. |

| 0.2 % | Disinfection of floors, walls, latrines, etc. during a cholera outbreak. |

| 0.1 % | Disinfection of washing facilities, bins. |

| 0.05 % | Cleaning of hands, skin, clothing, bedding. |

Never spray humans with chlorine spray, even as an infection control measure. This has serious detrimental health effects. 13

Iron and Manganese Removal

Chlorine can also be used before other water treatment processes, particularly to facilitate the removal of iron and manganese from the water. This would rarely be applicable to humanitarian settings and this topic is not discussed further here.

Disinfection of soil, latrines, etc.

Chlorine is ineffective against pathogens in the soil or in sludge. Therefore, chlorine cannot be used for desludging or decommissioning of pit latrines, or as part of solid waste or cleanup campaigns.

References

- WHO (2017), Guidelines for Drinking Water Quality, 4th Edition.

- Ariel Branz, Matthew Levine, Lilian Lehmann, Andy Bastable, Syed Imran Ali, Khalid Kadir, Travis Yates, David Bloom, and Daniele Lantagne (2017), Chlorination of drinking water in emergencies: a review of knowledge to develop recommendations for implmentation and research needed

- WHO (1996), Fact Sheet 2.17: Chlorination Concepts

- CDC, Free Chlorine Testing

- Sphere (2018), Sphere Handbook.

- Syed Imran Ali, Syed Saad Ali, Jean-Francois Fesselet (2021), Evidence-based chlorination targets for household water safety in humanitarian settings: Recommendations from a multi-site study in refugee camps in South Sudan, Jordan, and Rwanda.

- MSF (2010), Public Health Engineering in Precarious Situations [2nd edition]

- Robert Spon. (2008). Do You Really Have a Free Chlorine Residual? Opflow, 34(6), 24-27.

- Environmental Protection Agency (2017), Emergency Disinfection of Drinking Water

- Daniele S. Lantagne (2009), Viability of Commercially Available Bleach for Water Treatment in Developing Countries American Journal of Public Health 99

- WHO (1996), Fact Sheet 2.20: Sodium Hypochlorite

- WHO (1996), Fact Sheet 2.19: Calcium Hypochlorite

- Mehtar, S., Bulabula, A.N.H., Nyandemoh, H. et al. (2016) Deliberate exposure of humans to chlorine-the aftermath of Ebola in West Africa. Antimicrob Resist Infect Control 5, 45

- World Health Organisation (1999): Guidelines for Safe Disposal of Unwanted Pharmaceuticals in and after Emergencies

- WHO (1996), Fact Sheet 2.22: Dosing Hypochlorite Solutions

- Iqbal Q, Lubeck-Schricker M, Wells E, Wolfe MK, Lantagne D (2016) Shelf-Life of Chlorine Solutions Recommended in Ebola Virus Disease Response. PLoS ONE 11(5)

- WHO (1996), Fact Sheet 2.21: Continuous Chlorination of Dug Wells

- Marlene K. Wolfe, Karin Gallandat, Kyle Daniels, Anne Marie Desmarais, Pamela Scheinman, Daniele Lantagne (2017), Handwashing and Ebola virus disease outbreaks: A randomized comparison of soap, hand sanitizer, and 0.05% chlorine solutions on the inactivation and removal of model organisms Phi6 and E. coli from hands and persistence in rinse water

- WHO (1996), Fact Sheet 2.25: Cleaning and Disinfection of Wells

- WHO (1996), Fact Sheet 2.26: Cleaning and Disinfection of Pipelines

- WHO (1996), Fact Sheet 2.27: Cleaning and Disinfection of Pipelines

- WHO (1996), Fact Sheet 2.28: Cleaning and Disinfection of Tranker Trucks

- Karin Gallandat, Marlene K. Wolfe, and Daniele Lantagne (2017), Surface Cleaning and Disinfection: Efficacy Assessment of Four Chlorine Types Using Escherichia coli and the Ebola Surrogate Phi6. Environmental Science & Technology 2017 51 (8), 4624-4631

- World Health Organization. Regional Office for the Eastern Mediterranean (2017) Health laboratory facilities in emergency and disaster situations, Second Edition Annex 16: Information on bleach preparation